Company News

Company News

- Carved aluminum plate is how to make

- Aluminum veneer installation method

- Hyperbolic aluminum veneer price cost analysis

- Measurement is an important link in the installation and construction of aluminum veneer

- Brief introduction of punching aluminum veneer performance

Industry dynamics

- The use of curved aluminum veneer

- How is the wood grain on the wood grain aluminum veneer made?

- Does Foshan have hyperbolic aluminum veneer manufacturer?

- How much do you know about the definition of carved aluminum plate

- Detailed analysis of aluminum veneer curtain wall construction

FAQ

- What are the main applications of punching aluminum veneer space

- Aluminum veneer is divided into different types

- Why do aluminum veneer need welding

- Process Technology of Carved Aluminum Plate

- General problems of aluminum veneer workshop

Contact Us

Mobile phone: 13074271912

Tel: 130-7427-1912

Email: 3457334962@qq.com

Address: Jianmei Building, Dali Town, Nanhai District, Foshan City, Guangdong Province, China

Company News

What are the requirements for the processing and manufacturing technology of hollow aluminum veneer?

- Author: Kaimai

- Release date: 2022-05-13 11:30:08

- 点击:0

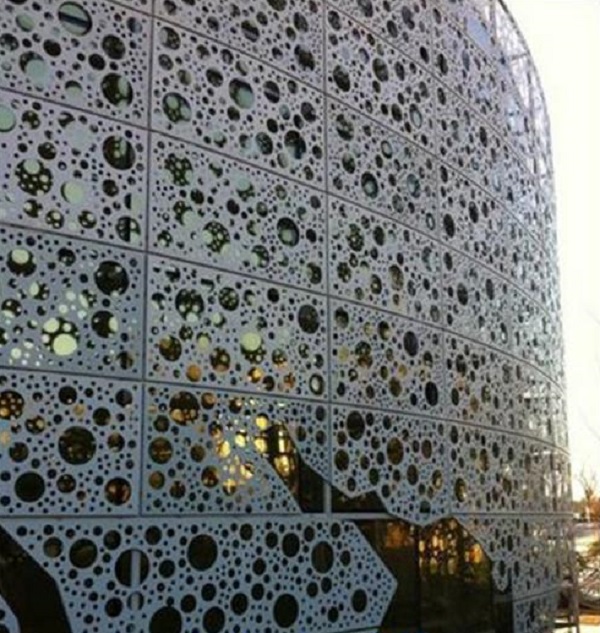

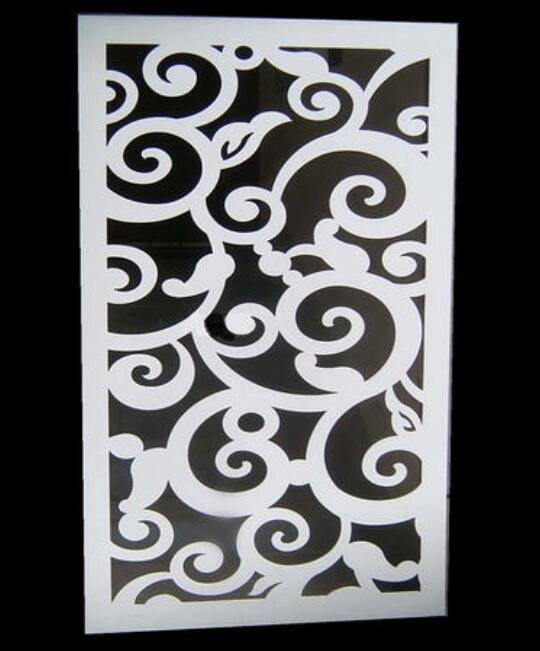

镂空是一种雕刻技术,需要非常细致的工艺。设计师大胆地将这一元素融入到现代建筑的幕墙装饰中,是一种充满时代个性的装饰艺术。镂空Aluminum veneerIt can make the flat panel extend rapidly, give people a deep sense of space, and have the function of light transmission and warmth. Hole patterns of different patterns, sizes and densities vary and match to make the surface of the object dynamic. Integration of different shapes and environments for shaped processing. The hollow aluminum veneer makes the lines more smooth and soft, breaks through the traditional modeling concept, and is more and more suitable for various modern clubs, office buildings and other occasions.

1. Sheet metal processing requirements

According to the processing requirements of the manufacturer, a complete set of bending machines is required for cutting, punching, bending and processing bent plates, which can realize the processing of hollow aluminum veneer with various complex shapes of basic sizes. The argon arc welding and high-frequency welding equipment of aluminum can ensure the accurate completion of the welding and angle sealing of the formed aluminum veneer and the nailing of the reinforcing ribs. Mechanized grinding and polishing equipment, automatic pretreatment tank and newly designed spray booth and oven can complete the processing of super-large and super-long plates to ensure that the surface of the product can meet the coating requirements of the substrate required for spraying.

Hollow aluminum veneer customization

2. Spraying processing requirements

Chemical pretreatment is to remove organic and inorganic stains on the metal surface with a chemical solution, then remove the natural oxide layer, and then use chemicals to generate an oxide film to prevent rust on the metal surface and permanently adhere to the paint. Using the automatic electrostatic spraying line in electrostatic coating, the fluorocarbon coating is sprayed layer by layer on the metal base of the hollow aluminum veneer according to the process requirements, and then baked and cured at a specific temperature and time.

3. Quality requirements

Quality inspection packaging: the use of high-precision special testing equipment for strict inspection of product quality, to ensure that the dimensional accuracy of the hollow aluminum veneer in line with enterprise standards, paint film quality in line with standards. The construction process of aluminum plate and aluminum veneer is basically the same. When the manufacturer processes the required shape and specifications, the installation and construction freedom is greater, while the aluminum-plastic plate is processed by the manufacturer. In addition, in terms of the guarantee of delivery time during the installation and construction process, the mass production of hollow aluminum veneer is much faster than that of aluminum-plastic panels, and the construction period and schedule guarantee system are also higher.

Customer service QQ

Customer service QQ